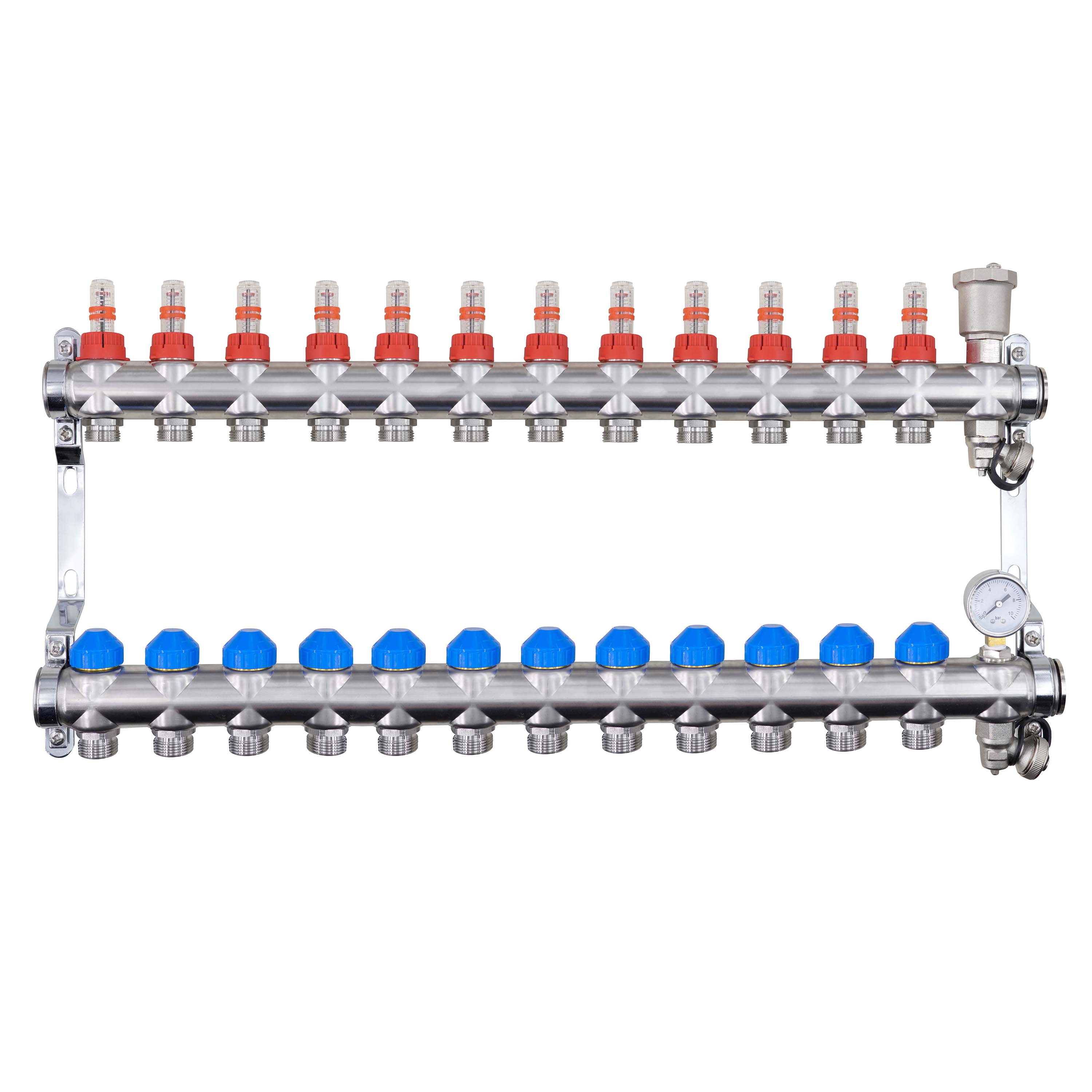

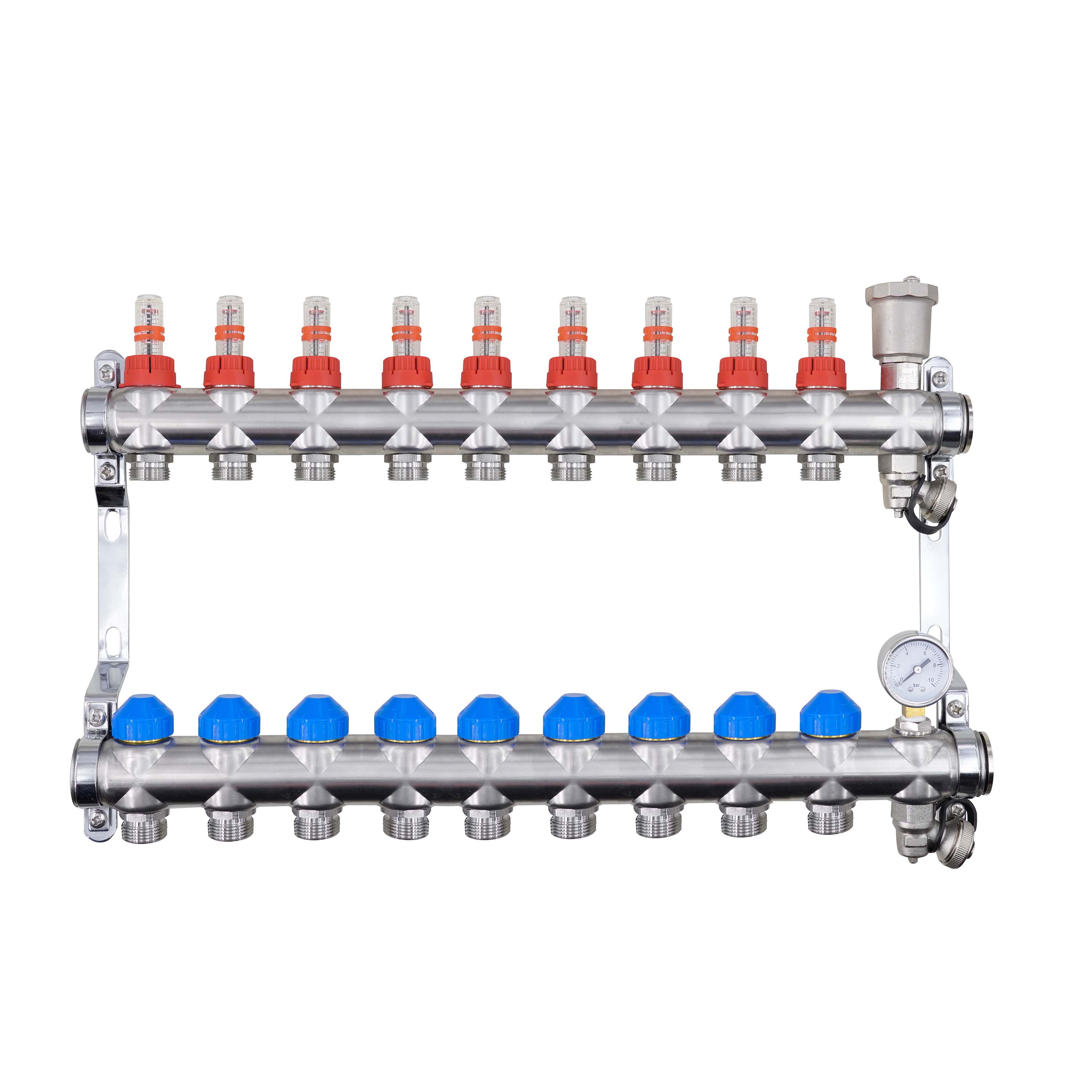

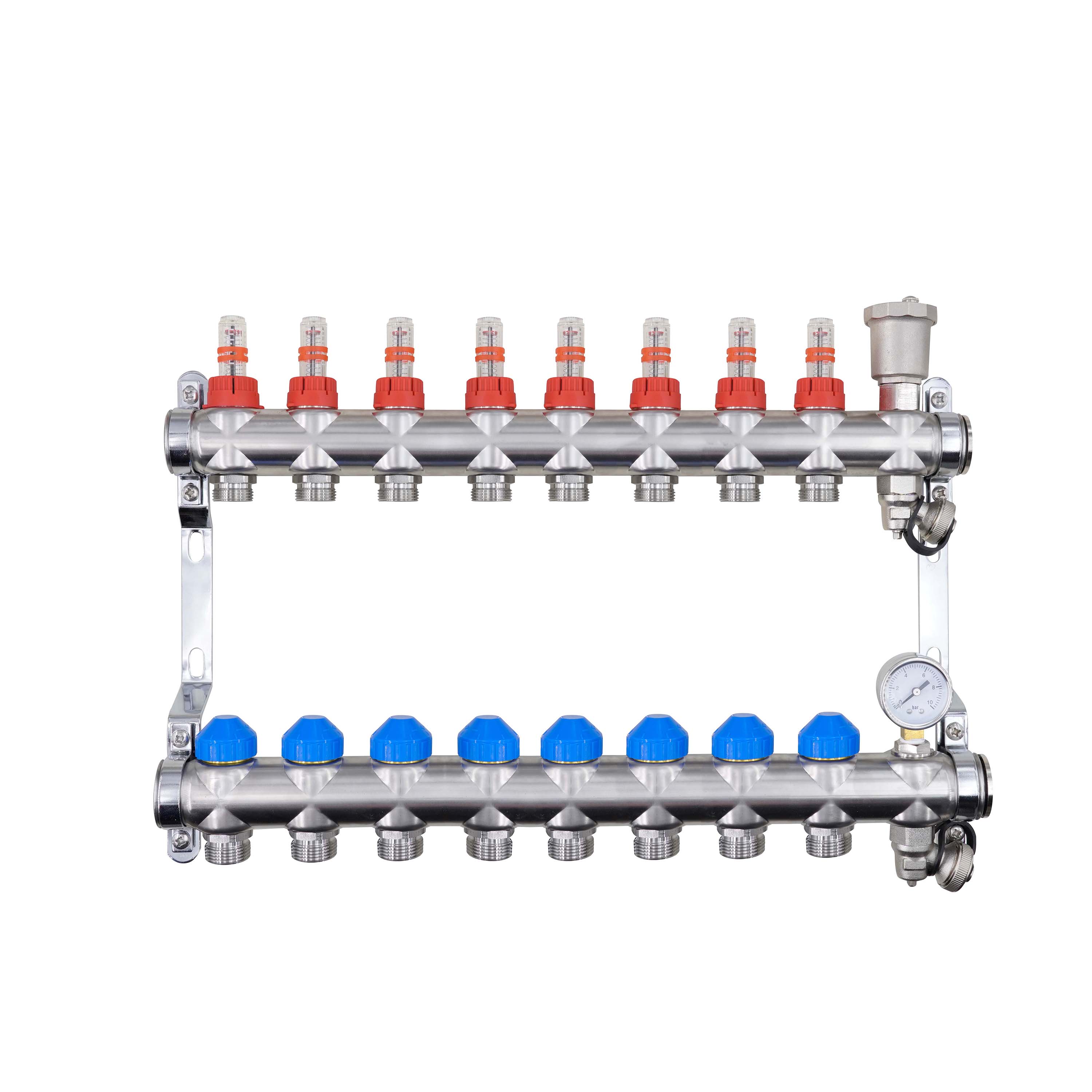

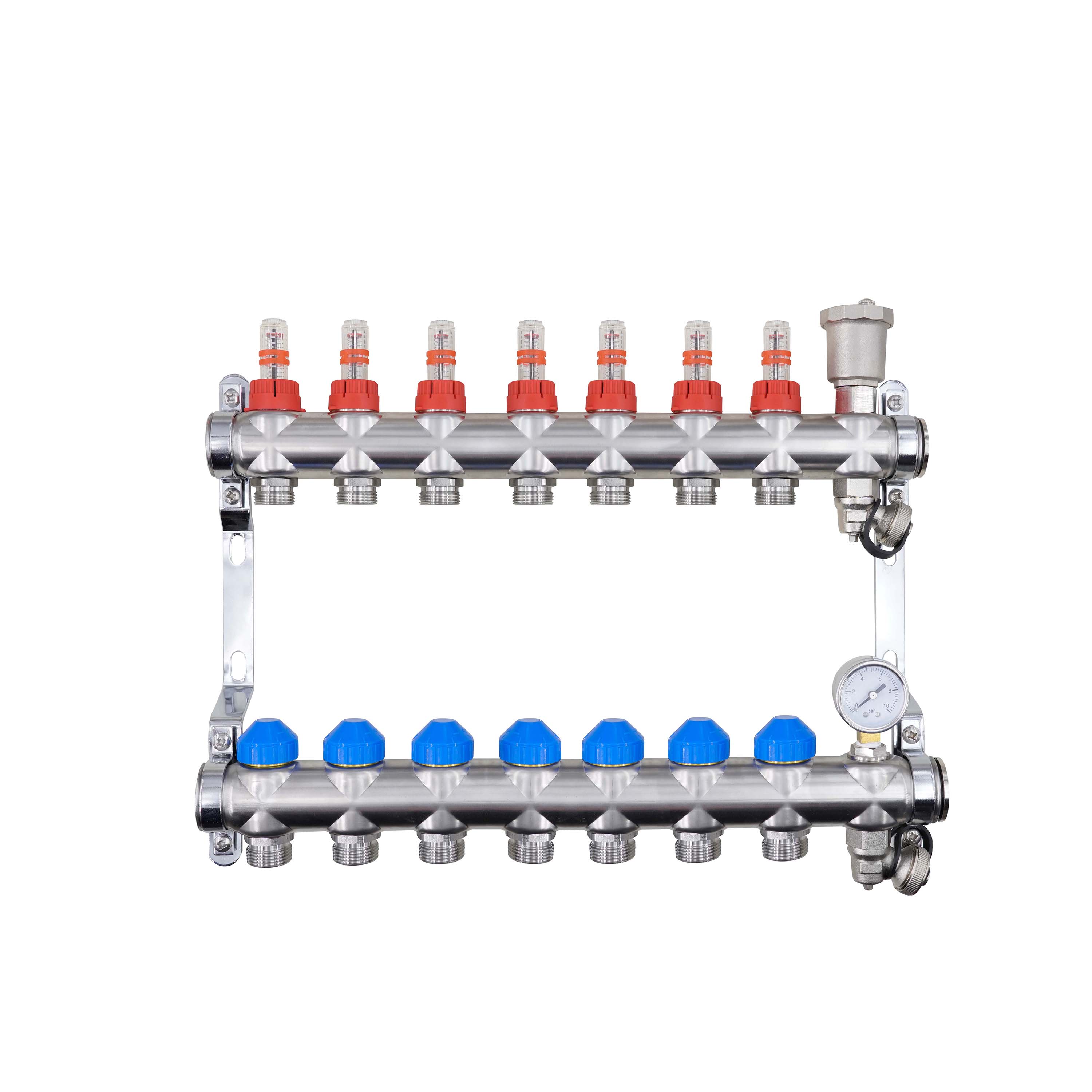

Tritherm Ultimate Auto-Balancing Manifold

£124.69 – £405.15Price range: £124.69 through £405.15 excl VAT

Advanced Dynamic Flow Control technology, this premium stainless steel manifold automatically adjusts internal valves to maintain a constant, precise flow rate to every room—regardless of pressure fluctuations or how many zones are open.

The Tritherm Ultimate Auto-Balancing Manifold is a premium, stainless steel distribution system designed for high-efficiency underfloor heating applications. With advanced Dynamic Flow Balancing technology, this manifold automatically maintains the precise flow rate for each circuit independently, making it an essential asset for ensuring perfectly balanced temperatures across multiple rooms.

The kit comes complete with a pre-assembled delivery and return manifold, flow meters, dynamic balancing valves, automatic air vents, and drain valves, ensuring you have a “set and forget” solution for complex heating systems.

Key Product Features

| Feature | Detail | Benefit |

| Dynamic Balancing | Auto-adjusts internal valve cartridge. |

Maintains exact flow rates regardless of pressure fluctuations or other zones closing.

|

| Flow Capacity | 10 – 250 l/h per circuit. |

Wide adjustment range suitable for small bathrooms to large open-plan living areas.

|

| High Pressure Handling | Works up to 150 kPa (1.5 Bar) differential. |

Handles high pump pressures and system fluctuations without noise or instability.

|

| Independent Control | Isolated circuit regulation. |

Adjusting one loop does not affect the flow rate of any other loop.

|

| Construction | 304 Stainless Steel. |

Superior corrosion resistance and durability compared to standard brass manifolds. |

Intelligent Flow Control & Efficiency

Combines robust construction with smart internal mechanics to ensure every floor loop receives exactly the heat it needs.

- Automatic Pressure Adaptation: The return manifold features a specialized bonnet cartridge with a controlled deformation spring. If pressure rises (e.g., when other zones close), the spring instantly alters the cross-section of the fluid passage to keep the flow rate stable.

- “Set & Forget” Precision: The maximum design flow rate for each individual circuit can be set once and maintained accurately at all times. This eliminates the need for complex, repetitive manual balancing.

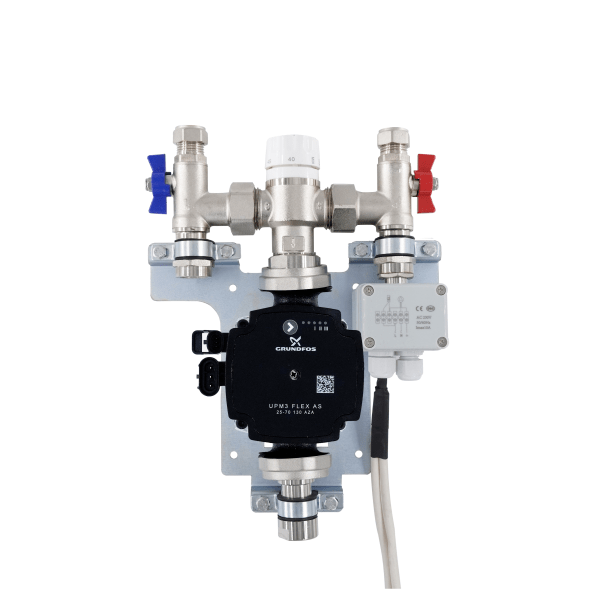

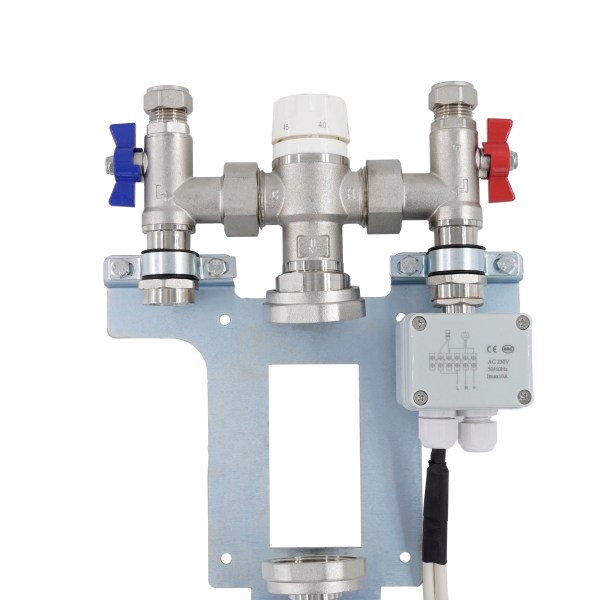

- Optimized Temperature Control: When used with thermo-electric actuators and room thermostats, the dynamic balancing allows for more effective and efficient temperature control in multiple interior rooms.

System Compatibility & Performance

Designed for the rigors of modern HVAC systems, built to handle various operating conditions while simplifying the installer’s job.

- Versatile Fluid Handling: Suitable for use with water and glycol solutions (up to 30% concentration), making it compatible with heat pumps and standard boilers.

- Actuator Ready: The return valves are pre-arranged for M30x1.5 thermo-electric actuators. These can be easily installed after the flow rates have been preset.

- Integrated Diagnostics: Includes flow meters (0-5 l/min) on the supply bar and a pressure gauge to provide real-time visual feedback on system performance.

Technical Specifications

| Detail | Specification |

| Material |

304 Stainless Steel (Manifold), EPDM Gaskets

|

| Max Working Pressure |

6 Bar (Tested to 10 Bar)

|

| Working Diff. Pressure |

30/40 kPa to 150 kPa

|

| Flow Setting Range |

10 – 250 l/h per circuit

|

| Operating Temp |

5°C to 70°C

|

| Actuator Connection |

M30 x 1.5mm

|

| Center Distance |

50mm between outlets

|

| Warranty | Lifetime (Subject to terms) |

Installation & Maintenance

Reliability is key for professional heating systems. designed for longevity but requires proper setup to function correctly.

- Precise Commissioning: Flow rates are preset using the included Regulation Key (scale 0-40). This must be done before installing any actuators.

- System Hygiene: If installing into a system with high levels of sludge or contaminants, it is recommended to flush the system with a chemical cleaner before installation to protect the dynamic valve mechanism.

- Routine Checks: The manifold is designed for closed-circuit systems. Ensure mineral oil-based lubricants are avoided as they may damage the EPDM gaskets

| Option | 2 Port, 3 Port, 4 Port, 5 Port, 6 Port, 7 Port, 8 Port, 9 Port, 10 Port, 11 Port, 12 Port |

|---|

Reviews

There are no reviews yet.